Home > Products > Steel Pipe & Tube > P275nl1 P355n P355nh P355nl1 P275nl2 Seamless Steel Pipe in Stock

P275nl1 P355n P355nh P355nl1 P275nl2 Seamless Steel Pipe in Stock

ProductP275NL1 P355N P355NH P355NL1 P275NL2 seamless steel pipe in stockStandard EN10216 MaterialP275NL1 P355N P355NH P355NL1 P275NL2 Surface Black paint, varnish, oil, galvanized Pipe Length 5.8 m to 12 m, can be customized according to the length requirements Pipe Ends Plain Ends, Beveled Ends End......

Send Inquiry

Product Description

| Product | P275NL1 P355N P355NH P355NL1 P275NL2 seamless steel pipe in stock |

| Standard | EN10216 |

| Material | P275NL1 P355N P355NH P355NL1 P275NL2 |

| Surface | Black paint, varnish, oil, galvanized |

| Pipe Length | 5.8 m to 12 m, can be customized according to the length requirements |

| Pipe Ends | Plain Ends, Beveled Ends |

| End Protector | 1. Plastic caps (small OD) 2. Iron protector (large OD) |

| Application | Fluid pipe, oil pipe, gas pipe, structure pipe, boiler tubes |

| Test | Chemical Component Analysis, Mechanical Properties, Technical Properties, Exterior Size |

| Productivity | 50000 tons per month |

| Min Order | 20 ton |

| Remark | Special design available according to requirement |

Chemical composition % of steel P275NL1 (1.0488)

| According EN 10216-3:2014: 0.5=< Mn=<1.5; S=<0.008; N=<0.02; Ti=<0.04; |

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | - |

| max 0.16 | max 0.4 | 0.8 - 1.5 | max 0.5 | max 0.025 | max 0.015 | max 0.3 | max 0.08 | max 0.05 | max 0.012 | max 0.05 | max 0.03 | max 0.02 | max 0.3 | Nb+Ti+V < 0.05 |

Chemical composition % of steel P355N (1.0562)

| According EN 10216-3:2014: C=<0.2; 0.9=< Mn=<1.7; S=<0.02; N=<0.02; Ti=<0.04; |

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | - |

| max 0.18 | max 0.5 | 1.1 - 1.7 | max 0.5 | max 0.025 | max 0.015 | max 0.3 | max 0.08 | max 0.1 | max 0.012 | max 0.05 | max 0.03 | max 0.02 | max 0.3 | Nb+Ti+V < 0.12 |

Chemical composition % of steel P355NH (1.0565)

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | - |

| max 0.18 | max 0.5 | 1.1 - 1.7 | max 0.5 | max 0.025 | max 0.015 | max 0.3 | max 0.08 | max 0.1 | max 0.012 | max 0.05 | max 0.03 | max 0.02 | max 0.3 | Nb+Ti+V < 0.12 |

Chemical composition % of steel P355NL1 (1.0566)

| According EN 10216-3:2014: 0.9=< Mn=<1.7; S=<0.008; N=<0.02; Ti=<0.04; |

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | - |

| max 0.18 | max 0.5 | 1.1 - 1.7 | max 0.5 | max 0.025 | max 0.015 | max 0.3 | max 0.08 | max 0.1 | max 0.012 | max 0.05 | max 0.03 | max 0.02 | max 0.3 | Nb+Ti+V < 0.12 |

Chemical composition % of steel P275NL2 (1.1104)

| According EN 10216-3:2014: 0.5=< Mn=<1.5; S=<0.005; N=<0.02; Ti=<0.04; |

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | Nd | - |

| max 0.16 | max 0.4 | 0.8 - 1.5 | max 0.5 | max 0.02 | max 0.01 | max 0.3 | max 0.08 | max 0.05 | max 0.012 | max 0.05 | max 0.03 | max 0.02 | max 0.3 | max 0.05 | Nb+Ti+V < 0.05 |

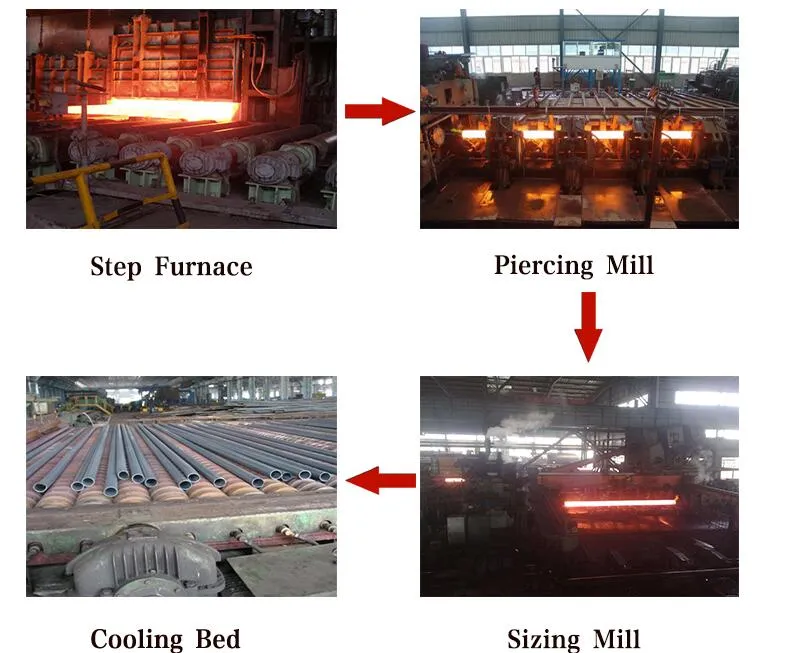

Manufacturing:

Packing:

Related Category

Steel & Products

Steel Pipe & Tube

Steel Coil & Strip

Steel Sheet & Plate

Stainless Steel

Aluminum

Non-ferrous Metal & Products

Copper

Alloy

Tungsten

Titanium

Iron & Products

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.