JIS G3445 Stkm13A Steel Tube Seamless

SPECIFICATION:Standard & MaterialCarbon SteelASTM A519 StandardMT1010, MT1020, 1008, 1010, 1018, 1020, 1025, 1030, 1045, 1518JIS G3445 StandardSTKM11A STKM12A STKM12B STKM12C STKM13A STKM13B STKM13C STKM14A STKM14B STKM14C STKM15A STKM15C STKM16A STKM16C STKM17A STKM17C STK......

Send Inquiry

Product Description

SPECIFICATION:

CHEMICAL COMPOSITION:

MECHANICAL PROPERTIES:

DELIVERY CONDITION:

QUALITY CONTROL:

20 -60 Centigrade Impact Testing Machine DM2500M Metallographic Microscope

HRS-ISO Rockwell Hardness Tester MAXXLMFO4 Direct Reading Spectrometer

MH2000 Carbon Sulfur Analyzer SHT4605 Universal Testing Machine

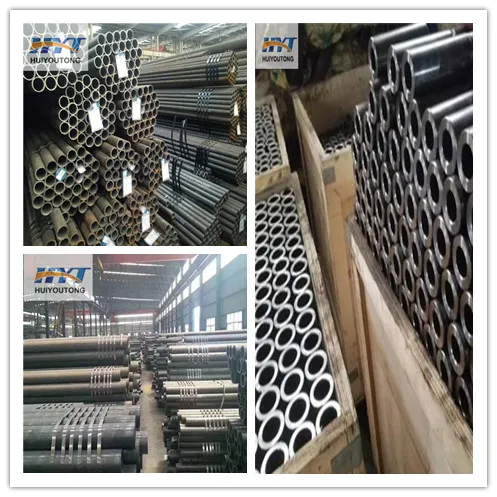

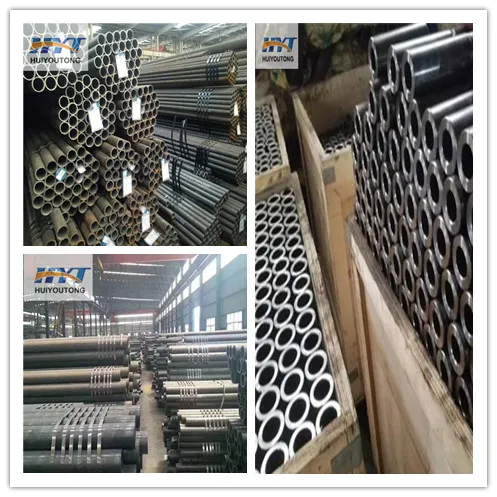

OUR INVENTORY:

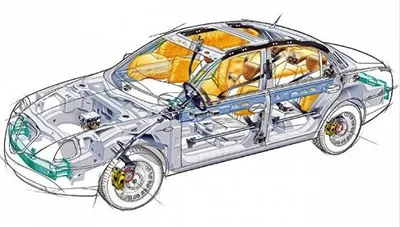

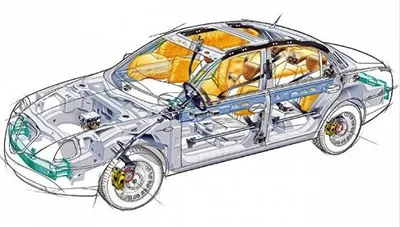

PRODUCT APPLICATION:

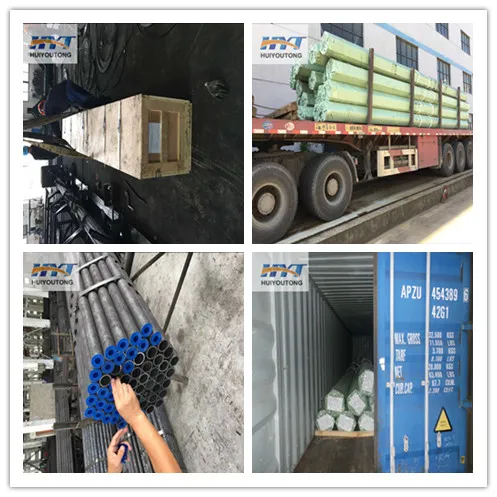

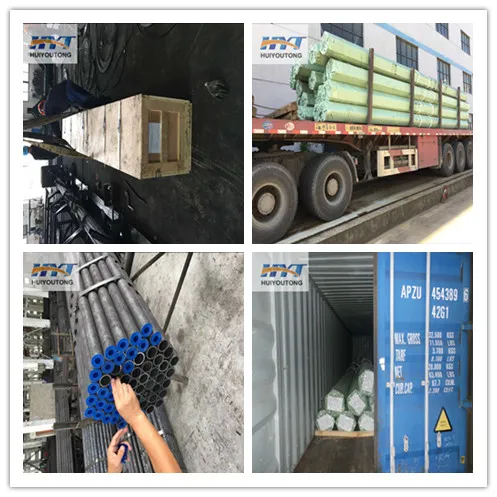

PRODUCT PACKAGING & SHIPMENT:

FAQ:

1. Q: What's the surface roughness of seamless mechanical tubing you could do ?

A:Surface Roughness: a=0.02~0.4micron or depends on the customer's requirement.

2. Q: How's the straightness of cold drawn mechanical tubes?

A: Straightness:0.3~0.8mm/1000mm

3. Q: Shall we get the discount if repeating our orders?

A: Of course, biggest discount will be shared with the regular customers.

| Standard & Material | Carbon Steel | ASTM A519 Standard | MT1010, MT1020, 1008, 1010, 1018, 1020, 1025, 1030, 1045, 1518 |

| JIS G3445 Standard | STKM11A STKM12A STKM12B STKM12C STKM13A STKM13B STKM13C STKM14A STKM14B STKM14C STKM15A STKM15C STKM16A STKM16C STKM17A STKM17C STKM18A STKM18B STKM18C STKM19A STKM19C STKM20A | ||

| JIS G3473 Standard | STC370, STC440, STC510A, STC510, STC540, STC590A, STC590B | ||

| DIN 2391 Standard | St 35, St45, St52 | ||

| EN 10297-1 Standard | E235, E275, E315, E355, E470 | ||

| EN 10305-1 Standard | E215, E235, E355 | ||

| EN 10305-4 Standard | E215, E235, E355 | ||

| BS 6323-3 Standard | HFS 3, HFS 4, HFS 5, HFS 8 | ||

| NF A49-311 | TU 37-b, TU 52-b, TU 56-b, TU XC35 | ||

| Alloy Steel | ASTM A519 Standard | 1345, 3140, 4130, 4135, 4140, 4150, 4320, 4340, 5120, 5130 | |

| JIS G3429 Standard | STH11, 12 STH21, 122 STH31 | ||

| JIS G3441 Standard | SCR420TK, SCM415TK, SCM418TK, SCM420TK, SCM430TK, SCM440TK | ||

| Stainless Steel | ASTM A511 Standard | MT304, MT304L, MT310S, MT316, MT316L, MT317, MT321, MT347, MT403, MT410, MT431 | |

| ISO Standard | NACE MR-0175 | ||

| Size | Size Range | Tolerance | |

| OD | 6-325mm | -0.035 -- +0.045mm | |

| ID | 2-250mm | ±0.035mm | |

| WT | 1-32mm | depends on sizes | |

| Length | random or fixed length | +0-3.5mm | |

| Straightness | 0.15:1000, 0.4:1000, 0.5:1000 1:1000 or customized | ||

| Surface Roughness | Ra 0.02-0.4μm | ||

CHEMICAL COMPOSITION:

| Steel Grade | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Nb/V(%) |

| STKM11A | ≤0.12 | ≤0.35 | ≤0.60 | ≤0.040 | ≤0.040 | - |

| STKM12A | ≤0.20 | ≤0.35 | ≤0.60 | ≤0.040 | ≤0.040 | - |

| STKM12B | ≤0.20 | ≤0.35 | ≤0.60 | ≤0.040 | ≤0.040 | - |

| STKM12C | ≤0.20 | ≤0.35 | ≤0.60 | ≤0.040 | ≤0.040 | - |

| STKM13A | ≤0.25 | ≤0.35 | 0.30~0.90 | ≤0.040 | ≤0.040 | - |

| STKM13B | ≤0.25 | ≤0.35 | 0.30~0.90 | ≤0.040 | ≤0.040 | - |

| STKM13C | ≤0.25 | ≤0.35 | 0.30~0.90 | ≤0.040 | ≤0.040 | - |

| STKM14A | ≤0.30 | ≤0.35 | 0.30~1.00 | ≤0.040 | ≤0.040 | - |

| STKM14B | ≤0.30 | ≤0.35 | 0.30~1.00 | ≤0.040 | ≤0.040 | - |

| STKM14C | ≤0.30 | ≤0.35 | 0.30~1.00 | ≤0.040 | ≤0.040 | - |

| STKM15A | 0.25~0.35 | ≤0.35 | 0.30~1.00 | ≤0.040 | ≤0.040 | - |

| STKM15C | 0.25~0.35 | ≤0.35 | 0.30~1.00 | ≤0.040 | ≤0.040 | - |

MECHANICAL PROPERTIES:

| Steel Grade | Tensile Strength(N/mm²) | Yield Strength(N/mm²) |

| STKM11A | ≥290 | - |

| STKM12A | ≥340 | ≥175 |

| STKM12B | ≥390 | ≥275 |

| STKM12C | ≥470 | ≥355 |

| STKM13A | ≥370 | ≥215 |

| STKM13B | ≥440 | ≥305 |

| STKM13C | ≥510 | ≥380 |

| STKM14A | ≥410 | ≥245 |

| STKM14B | ≥500 | ≥355 |

| STKM14C | ≥550 | ≥410 |

| STKM15A | ≥470 | ≥275 |

| STKM15C | ≥580 | ≥430 |

DELIVERY CONDITION:

| +C(BK) | Cold drawn/hard.After the last cold forming,no heat treatment. |

| +LC(BKW) | Cold drawn/soft.After the last heat treatment follows the cold drawing there is a light finishing pass. |

| +SR(BKS) | Cold drawn and stress relieved annealed. After the final cold drawing process the tubes are stress relieved annealed in a controlled atmosphere. |

| +A(GBK) | After the final cold drawing process the tubes are stress relieved annealed in a controlled atmosphere. |

| +N(NBK) | Normalized. After the last cold drawing process the tubes are annealed in a controlled atmosphere. |

QUALITY CONTROL:

20 -60 Centigrade Impact Testing Machine DM2500M Metallographic Microscope

HRS-ISO Rockwell Hardness Tester MAXXLMFO4 Direct Reading Spectrometer

MH2000 Carbon Sulfur Analyzer SHT4605 Universal Testing Machine

OUR INVENTORY:

PRODUCT APPLICATION:

PRODUCT PACKAGING & SHIPMENT:

FAQ:

1. Q: What's the surface roughness of seamless mechanical tubing you could do ?

A:Surface Roughness: a=0.02~0.4micron or depends on the customer's requirement.

2. Q: How's the straightness of cold drawn mechanical tubes?

A: Straightness:0.3~0.8mm/1000mm

3. Q: Shall we get the discount if repeating our orders?

A: Of course, biggest discount will be shared with the regular customers.

Related Category

Steel & Products

Steel Pipe & Tube

Steel Coil & Strip

Steel Sheet & Plate

Stainless Steel

Aluminum

Non-ferrous Metal & Products

Copper

Alloy

Tungsten

Titanium

Iron & Products

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.