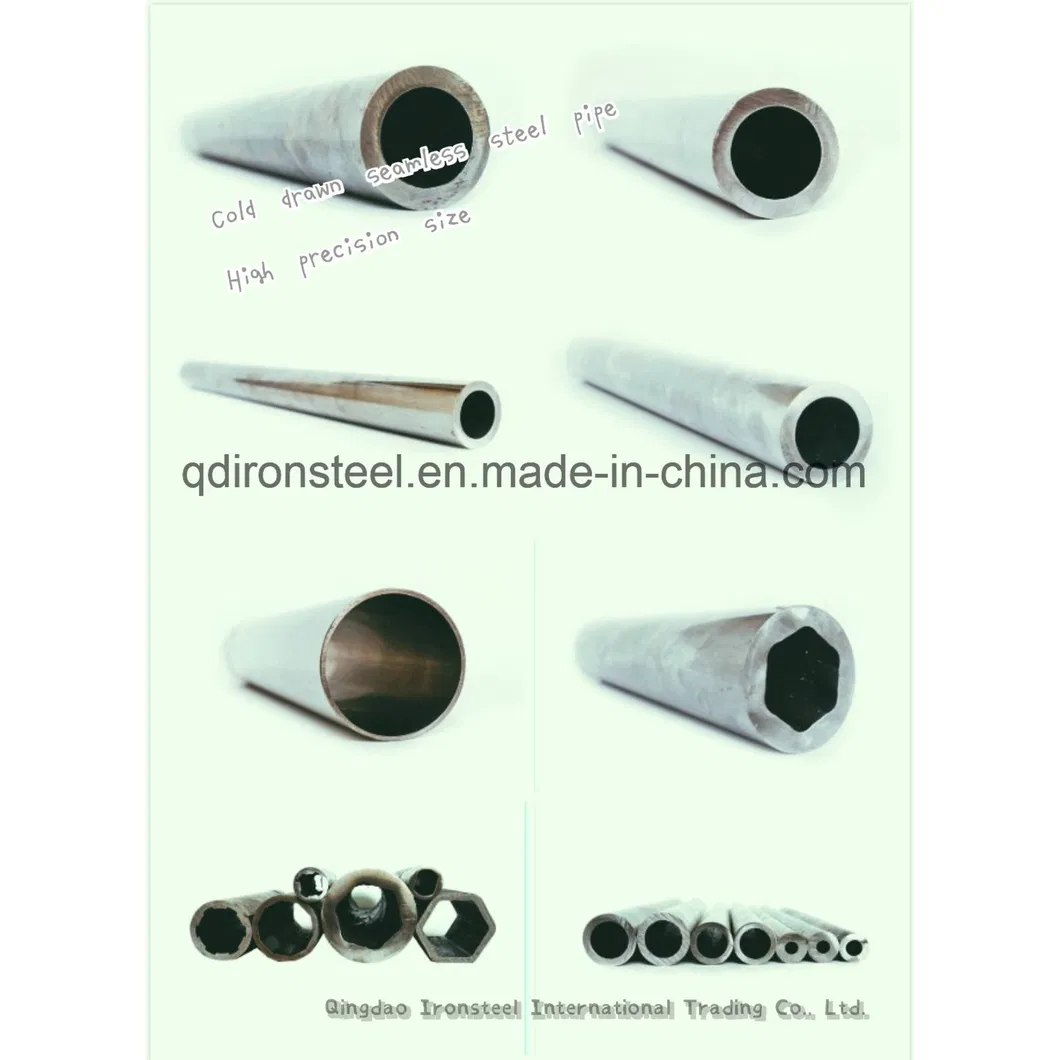

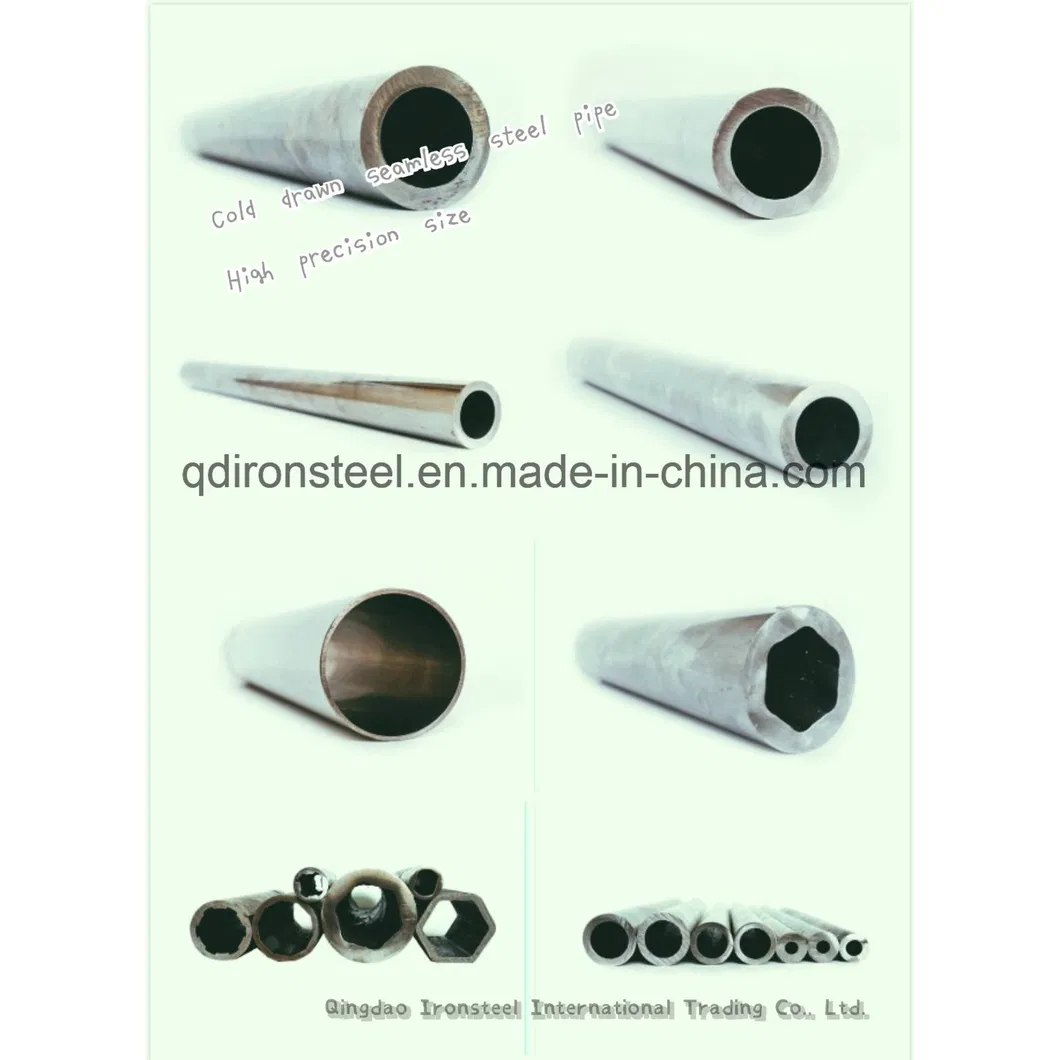

Home > Products > Steel Pipe & Tube > DIN2391 St52 Precise Cold Drawn Seamless Steel Pipe Steel Tube with Tolerance +/-0.1mm

DIN2391 St52 Precise Cold Drawn Seamless Steel Pipe Steel Tube with Tolerance +/-0.1mm

oleraance of size: ±0.05mm(outer diameter).OD: 21mm~416mmWall thickness: 0.8mm~20mmTechnique: Cold drawingStandard: ASME SA192/SA179, GB/T8162, GB/T8163, GB/T3639, DIN2391-2Steel material: 20#(AISI 1020/DIN1.0402 C22), 45#(ASTM 1045,DIN45), 20Cr, Q345B, etcWe are professional manufacturer......

Send Inquiry

Product Description

oleraance of size: ±0.05mm(outer diameter).

OD: 21mm~416mm

Wall thickness: 0.8mm~20mm

Technique: Cold drawing

Standard: ASME SA192/SA179, GB/T8162, GB/T8163, GB/T3639, DIN2391-2

Steel material: 20#(AISI 1020/DIN1.0402 C22), 45#(ASTM 1045,DIN45), 20Cr, Q345B, etc

We are professional manufacturer of cold drawn seamless steel pipe in China. Our seamless steel pipe with very high precision of size

Usage: widely used for mechanical processing, Automobile industry, hydraulic equipments

Advantages of our high precision seamless steel pipe:

1. Smaller caliber

2. Accept small qty order

3. Good surface treatment

4. The pipe with superior performance, suitable for mechanical making

Accurate size

Anti-corrosion Packing

Final Supply Conditions

Preicision Seamless Tube Size List

Chemical Composition of seamless steel pipe

Mechanical Properties of seamless steel pipe

OD: 21mm~416mm

Wall thickness: 0.8mm~20mm

Technique: Cold drawing

Standard: ASME SA192/SA179, GB/T8162, GB/T8163, GB/T3639, DIN2391-2

Steel material: 20#(AISI 1020/DIN1.0402 C22), 45#(ASTM 1045,DIN45), 20Cr, Q345B, etc

We are professional manufacturer of cold drawn seamless steel pipe in China. Our seamless steel pipe with very high precision of size

Usage: widely used for mechanical processing, Automobile industry, hydraulic equipments

Advantages of our high precision seamless steel pipe:

1. Smaller caliber

2. Accept small qty order

3. Good surface treatment

4. The pipe with superior performance, suitable for mechanical making

Accurate size

Anti-corrosion Packing

Final Supply Conditions

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and,thus, have a rather high resistance to deformation |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation.Appropriate further processing allows a certain degree of cold forming(e.g. bending expanding). |

| Cold finished and stress-relleved | BKS | Heat treatment is applled following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere |

Preicision Seamless Tube Size List

| OD (mm) | Thickness (mm) | OD (mm) | Thickness (mm) | OD (mm) | Thickness (mm) | OD (mm) | Thickness (mm) |

| Φ13.1 | 1.5-3 | Φ35.5 | 1.5-7 | Φ46.1 | 1.5-10 | Φ93 | 1.5-15 |

| Φ19.25 | 1.5-5 | Φ35.9 | 1.5-7 | Φ47.8 | 1.5-10 | Φ19-Φ121 | 1.5-15 |

| Φ22 | 1.5-5 | Φ36.6 | 1.5-7 | Φ49.2 | 1.5-10 | ||

| Φ22.2 | 1.5-5 | Φ38 | 1.5-8 | Φ49.5 | 1.5-10 | ||

| Φ25 | 1.5-6 | Φ38.4 | 1.5-8 | Φ52.3 | 1.5-10 | ||

| Φ26.3 | 1.5-6 | Φ40 | 1.5-10 | Φ53.8 | 1.5-10 | ||

| Φ27 | 1.5-6 | Φ40.2 | 1.5-10 | Φ57 | 1.5-10 | ||

| Φ28 | 1.5-6 | Φ40.9 | 1.5-10 | Φ59 | 1.5-10 | ||

| Φ30 | 1.5-6 | Φ41.3 | 1.5-10 | Φ60 | 1.5-11 | ||

| Φ30.25 | 1.5-6 | Φ41.6 | 1.5-10 | Φ62.5 | 1.5-11 | ||

| Φ30.9 | 1.5-6 | Φ42 | 1.5-10 | Φ74 | 1.5-11 | ||

| Φ31 | 1.5-7 | Φ43 | 1.5-10 | Φ75 | 1.5-11 | ||

| Φ32 | 1.5-7 | Φ44.5 | 1.5-10 | Φ76 | 1.5-11 | ||

| Φ35 | 1.5-7 | Φ45.8 | 1.5-10 | Φ89 | 1.5-15 |

| Material | Chemical composition (%) | ||||||

| C | Mn | P | S | Si | Ni | Cu | |

| 20# AISI 1020 | 0.17~0.23 | 0.35~0.65 | ≤0.035 | ≤0.035 | 0.17~0.37 | ≤0.3 | ≤0.25 |

| 45# ASTM1045, DIN45 | 0.42~0.5 | 0.5~0.8 | ≤0.04 | ≤0.045 | 0.17~0.37 | ≤0.25 | ≤0.25 |

| Steel material | Tensile Strength Mpa | Yield strength Mpa | Elongation % | Hardness | Straightness |

| 20# | ≥510 | ≥245 | ≥25 | ≤156HB | 0.3~1.0 |

| 45# | ≥647 | ≥355 | ≥16 | ≤HRC62 | 0.3~1.0 |

Related Category

Steel & Products

Steel Pipe & Tube

Steel Coil & Strip

Steel Sheet & Plate

Stainless Steel

Aluminum

Non-ferrous Metal & Products

Copper

Alloy

Tungsten

Titanium

Iron & Products

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.