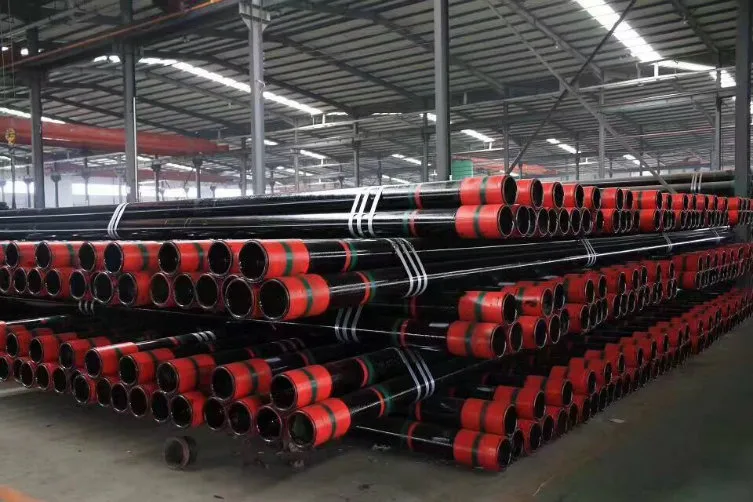

API 5CT/5b Tubing Pipe of 1.66''for Oilfield Service

Product name: API-5CT Seamless CasingGrade: J55 N80 P110Material: 34CrMo4,H40,J55, K55, N80,L80,M65,C90,T95,P110,Q125Standard: API 5CT Technique: Cold Drawn/Hot Rolled Application: Oil PipeOuter Diameter: 114.3-762mm Thickness: 2.87 - 30 mmSpecial Pipe:API PipeCertification: API S......

Send Inquiry

Product Description

| Product name: API-5CT Seamless Casing | Grade: J55 N80 P110 |

| Material: 34CrMo4,H40,J55, K55, N80,L80,M65,C90,T95,P110,Q125 | Standard: API 5CT |

| Technique: Cold Drawn/Hot Rolled | Application: Oil Pipe |

| Outer Diameter: 114.3-762mm | Thickness: 2.87 - 30 mm |

| Special Pipe:API Pipe | Certification: API |

| Secondary Or Not:Non-secondary | |

| Surface Treatment:Black,varnish | Section Shape:Round |

| Place of Origin: China (Mainland) |

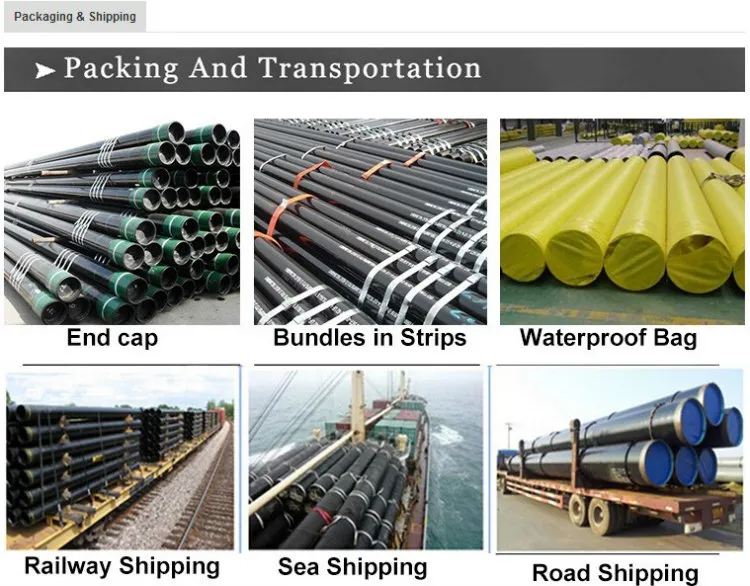

Packaging & Delivery

Packaging Details:

Seaworthy, Steel Shelf, Iron Pallet or as per customer's requirement

Delivery Times:20-55 days

API-5CT Seamless Tubing

Product DescriptionStandard | API 5CT/ ISO11960 | |

Grade | Group.1 | H40/PSL.1, J55/PSL.1, J55/PSL.2, J55/PSL.3, K55/PSL.1, K55/PSL.2, K55/PSL.3, N80(1)/PSL.1, N80(1)/PSL.2, N80(Q)/PSL.1, N80(Q)/PSL.2, N80(Q)/PSL.3 |

Group.2 | M65/PSL.1, M65/PSL.3, L80/PSL.2, L80(1)/PSL.1, L80(1)/PSL.3, L80(9Cr)/PSL.1, L80(13Cr)/PSL.1, C90/PSL.1, C90/PSL.2, C90/PSL.3, T95/PSL.1, T95/PSL.2T95/PSL.3 | |

Group.3 | P110/PSL.1, P110/PSL.2, P110/PSL.3, | |

Group.4 | Q125/PSL.1, Q125/PSL.2, Q125/PSL.3, | |

Minimum Order Quantity | 20 Ton | |

Outside Diameter Ranges | Tubing | 1.05 inch to 4 1/2 inch or 48.26mm to 114.3mm |

Casing | 4 1/2 inch to 30inch or 114.3mm to 762mm | |

Wall Thickness | According to API 5CT Standard | |

Length | Tubing | R1 (6.10m to 7.32m), R2 (8.53m to 9.75m), R3 (11.58m to 12.80m) |

Casing | R1 (4.88m to 7.62m), R2 (7.62m to 10.36m), R3 (10.36m to 14.63m) | |

Type | Seamless | |

Type of End-Finish | Tubing | P, I, N, U |

Casing | P, S, B, L | |

Casing and tubing for Sour Oil and Gas Service must have a good anti-SSCC (sulfide stresscorrosion and cracking)

performance in the environment where hydrogen sulfide corrosion exists.After an indepth study, we has successfully

developed tubular goods of the Cr-Mo series for this purpose with good hardenability and tempering stability that when

tempering takes places at certain temperatures uniform and fine sorbite structures can be obtained. Their mechanical

properties can meet fully the requirements of corresponding grades and their anti-SSC performance is excellent by

regulating the chemical composition and adopting different heat treatment procedures.

Characteristics:

1. Materials: The chemical compositions have been carefully determined to provide resistance to sulfide stress corrosion

as well as to insure complete through wall hardening.

2.Heat Treatment: Quenching and Tempering are conducted under rigid temperature control to assure homogeneous

physical properties and microstructures.

3.Micro Structure: These grades exhibit fully tempered martensite which is considered to be the most desirable for

resistance to sulfide stress corrosion cracking.

the predetermined maximum limit.

5. Sulfide Stress Cracking (SSC) Performance: Whole grades are designed for 85% or 90% SMYS in NACE condition.

Excellent SSC resistance has been achieved through rigorous, chemical composition, heat treatment, microstructure,

tensile properties, hardness and so on.

Pipe inspection:

A full length non destructive inspection is performed in accordance with API 5CT for external and internal, longitudinal

and transverse defects with a standard notch depth equal to 5% of the specified wall thickness.