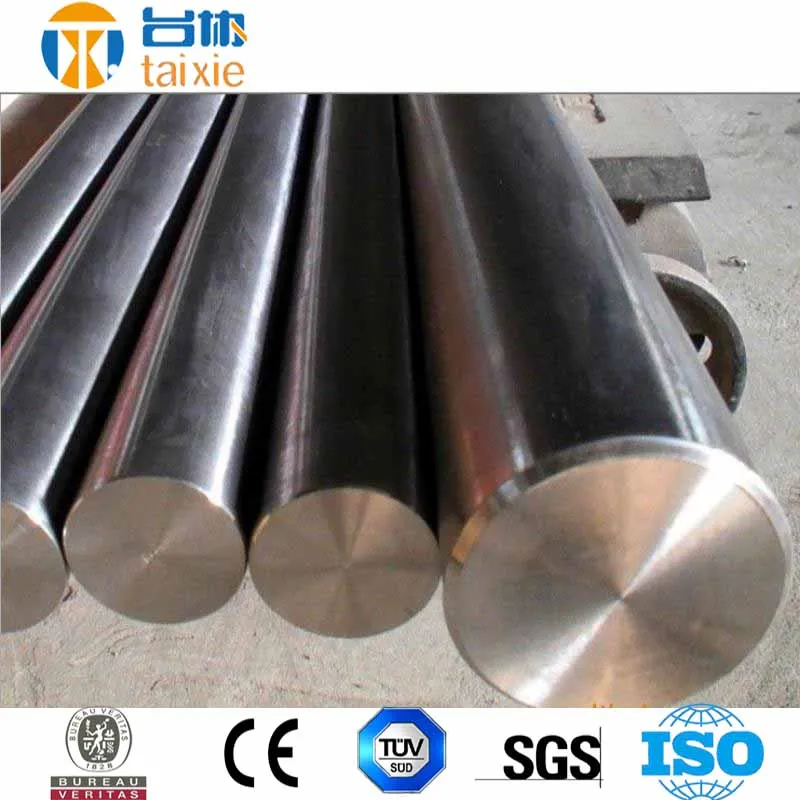

Haynes25 Uns R30605 AMS5759f AMS5537 ASTM F90 Steel Alloy

UNS N08020 ASTM B473 ASTM B463 alloy 20 steel sheetL605, also known as HAYNES25 is a cobalt-based alloy, with good formability and excellent high temperature performance in high temperature and high strength environment, the material can be anti-oxidation, car......

Send Inquiry

Product Description

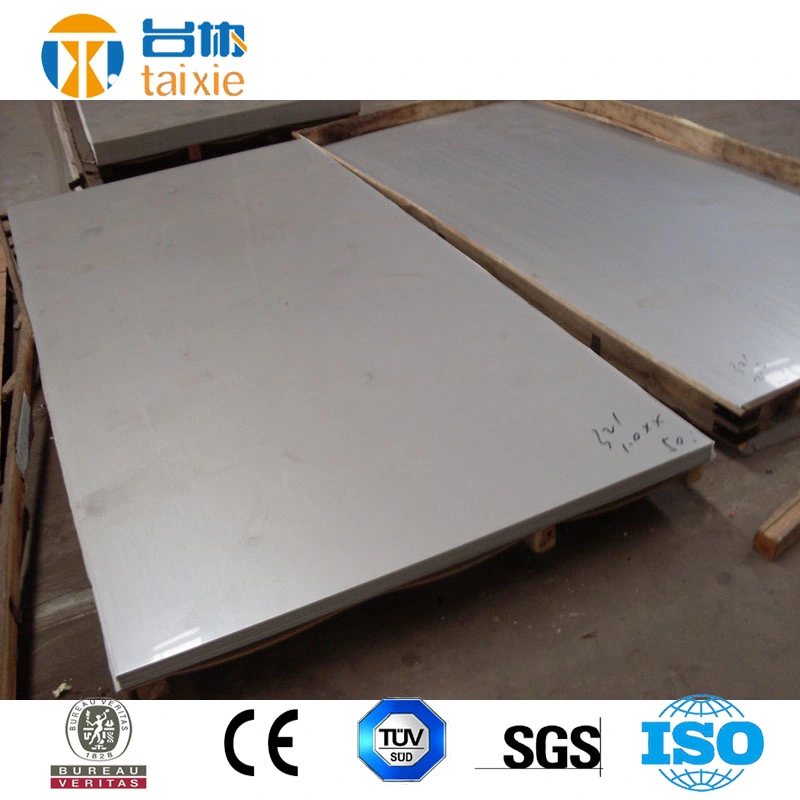

UNS N08020 ASTM B473 ASTM B463 alloy 20 steel sheet

L605, also known as HAYNES25 is a cobalt-based alloy, with good formability and excellent high temperature performance in high temperature and high strength environment, the material can be anti-oxidation, carbonation, easy to crack.

Chemical component %

Mechanical /Physical properties

Tensile strength σb (MPa): ≥560

Yield point σ0.2 (MPa):≥205

percentage reduction of area ψ (%):≥50

Elongationδ5 (%):≥40

Hardness: ≤201HRB

Grain size: by JIS G4511-2007

Processing performance

Machine plus

Conventional process can be processed L605, recommended the use of cobalt-containing high-speed steel or alloy steel tool. Compared to austenitic stainless steel (such as 304,321,347 stainless steel), L605 processing difficult. Very high cold hardening rate and the production process to produce a lot of heat makes processing difficult, it is recommended to use a small amount of feed and low speed.

welding

Available shielded metal arc welding, tungsten gas welding, metal pole gas welding to welding L605. Submerged arc welding is not recommended.

Weld clean the surface before welding, erase all stains and dry the surface.

Application

L605 is also used in the manufacture of jet engine components, including engine blades, combustion chamber, reburning device, turbine ring. L605 is also used for industrial furnaces, including high temperature furnace key parts of the flame device and lining.

Corrosion resistance

The L605 exhibits excellent resistance to high temperature corrosion gases in jet engine applications. 1600 ° F intermittent work and 2000 ° continuous oxidation resistance is also very good. In the heating process, L605 highly resistant to oxidation, does not appear The material is peeled off, while the material is resistant to a variety of chemical oxidants, especially resistant to a certain concentration and temperature of hydrochloric acid and nitric acid. Salt spray corrosion tolerance is very good.

Company Information:

Doris

Phone:+8613400008153

Tel: 0510-88222973

Fax: 0510-88222975

Web: taixie.en.made-in-china.com

Add:No.22, Xinfeng Road, Xin District, Wuxi, Jiangsu, China.

Over 16 years of specialist experience in Copper, Mould steel, steel alloy, aluminum ! Welcome to order and customized.

L605, also known as HAYNES25 is a cobalt-based alloy, with good formability and excellent high temperature performance in high temperature and high strength environment, the material can be anti-oxidation, carbonation, easy to crack.

Chemical component %

| C | Fe | Ni | Si | P | S | Mn |

| ≤0.3 | 2.5 | 63.0~70.0 | ≤0.5 | ≤0.024 | ≤0.024 | ≤2.00 |

Mechanical /Physical properties

Tensile strength σb (MPa): ≥560

Yield point σ0.2 (MPa):≥205

percentage reduction of area ψ (%):≥50

Elongationδ5 (%):≥40

Hardness: ≤201HRB

Grain size: by JIS G4511-2007

| Grade | C % | Si % | Mn % | P % | S % | Cr % | Mo % | Ni % | Other |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.06 | ≤0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | ≤0.06 | ≤0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | - | 6.0-8.0 | - |

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17-19 | - | 8-10.0 | - |

| 303 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.2 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | - | 8-10.5 | - |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | - | 9-13 | - |

| 309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 22-24 | - | 12-15 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.00 | ≤0.045 | ≤0.03 | 24-26 | - | 19-22 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 10-14 | - |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 12-15 | - |

| 317 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | 3-4 | 11-15 | - |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17-19 | - | 9-13 | Ti≥5×C |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.04 | ≤0.03 | 16-18 | - | ≤0.6 |

Processing performance

Machine plus

Conventional process can be processed L605, recommended the use of cobalt-containing high-speed steel or alloy steel tool. Compared to austenitic stainless steel (such as 304,321,347 stainless steel), L605 processing difficult. Very high cold hardening rate and the production process to produce a lot of heat makes processing difficult, it is recommended to use a small amount of feed and low speed.

welding

Available shielded metal arc welding, tungsten gas welding, metal pole gas welding to welding L605. Submerged arc welding is not recommended.

Weld clean the surface before welding, erase all stains and dry the surface.

Application

L605 is also used in the manufacture of jet engine components, including engine blades, combustion chamber, reburning device, turbine ring. L605 is also used for industrial furnaces, including high temperature furnace key parts of the flame device and lining.

Corrosion resistance

The L605 exhibits excellent resistance to high temperature corrosion gases in jet engine applications. 1600 ° F intermittent work and 2000 ° continuous oxidation resistance is also very good. In the heating process, L605 highly resistant to oxidation, does not appear The material is peeled off, while the material is resistant to a variety of chemical oxidants, especially resistant to a certain concentration and temperature of hydrochloric acid and nitric acid. Salt spray corrosion tolerance is very good.

Company Information:

Doris

Phone:+8613400008153

Tel: 0510-88222973

Fax: 0510-88222975

Web: taixie.en.made-in-china.com

Add:No.22, Xinfeng Road, Xin District, Wuxi, Jiangsu, China.

Over 16 years of specialist experience in Copper, Mould steel, steel alloy, aluminum ! Welcome to order and customized.

Related Category

Steel & Products

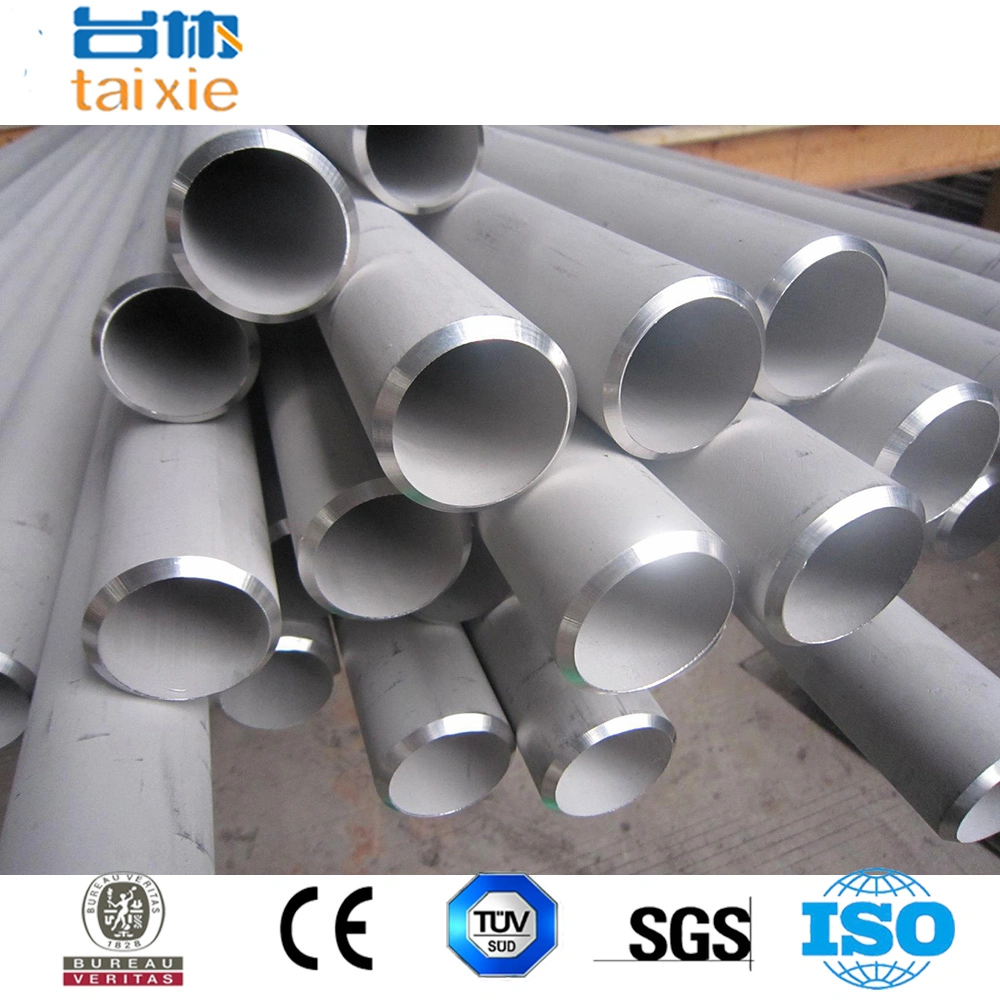

Steel Pipe & Tube

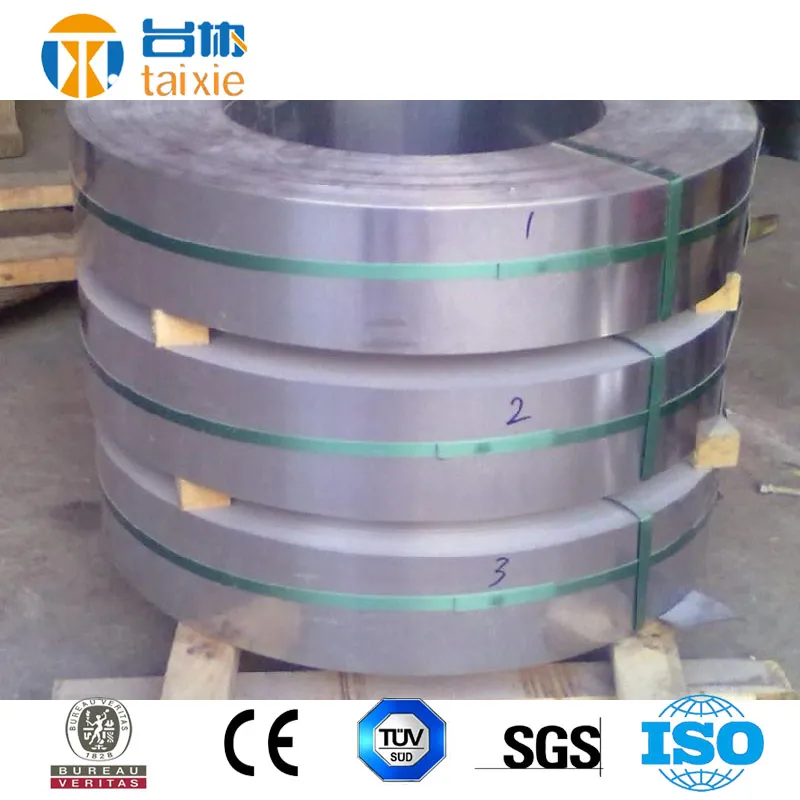

Steel Coil & Strip

Steel Sheet & Plate

Stainless Steel

Aluminum

Non-ferrous Metal & Products

Copper

Alloy

Tungsten

Titanium

Iron & Products

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.